In the world of interior design, cellular shades have emerged as a popular choice for both their aesthetic appeal and functional benefits. But what exactly makes these innovative window coverings stand out? In this article, we will delve into the intricate details of honeycomb blinds, exploring their unique structure, the craftsmanship behind their production, and the principles that govern their operation. We will also examine the various aspects of honeycomb design, including cell options, their light-blocking capabilities, and functions of this design. Whether you're considering honeycomb shades for your home or simply curious about their fascinating features, this comprehensive guide will illuminate all the aspects you need to know!

What Are Cellular Shades

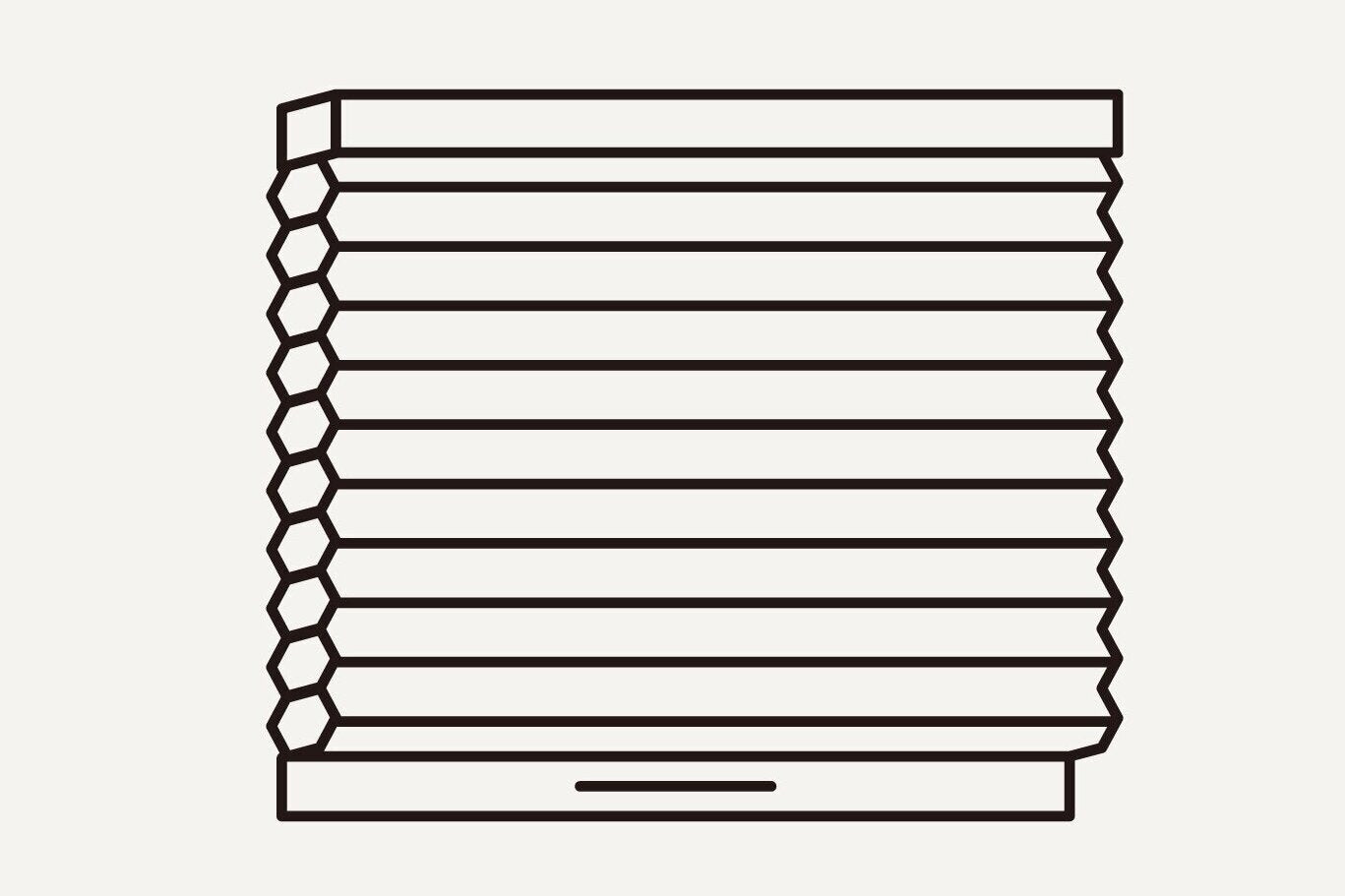

Cellular shades, also known as honeycomb blinds, are a type of window covering made from a series of fabric cells stacked in a honeycomb-shaped structure. These cells trap air, creating a barrier between the window and the room, which helps to regulate temperature by keeping heat out during the summer and retaining warmth during the winter. Typically, cellular window blinds consist of several key components:

- Mounting Brackets: These secure the cellular shades to your window frame.

- Headrail: This is the top part of cellular shade that houses the operating mechanism.

- Fabric: The main body of the cellular shades, available in various colors and cell sizes.

- Bottom Rail: This provides weight and stability to the cellular shades.

- Handle: Many designs feature a handle for easy operation.

Unlike traditional window treatments, cellular shades do not include valances and tilted slats, offering a sleek and streamlined look.

How are Cellular Shades Made

The process of crafting cellular shades is a fascinating blend of technology and artistry, utilizing a variety of materials and techniques. In this chapter, we will explore the detailed journey of how honeycomb shades are made, shedding light on the craftsmanship and engineering involved in the headrail, fabric, bottom rail, and handle.

Headrail

As the primary support structure for cellular shades, the headrail is typically a narrow, horizontal track made from materials like metal or durable plastic. It is designed to securely hold the fabric of the honeycomb shades in place while allowing for smooth operation. The choice of material significantly influences the processing techniques used.

Material Selection and Processing Techniques

Aluminum alloy is a popular choice for honeycomb blind headrails due to its lightweight nature and high strength. In situations where additional corrosion resistance or cost-effectiveness is necessary, PVC or composite materials may also be used for the headrail. Aluminum alloy headrails are typically manufactured through an extrusion process, where the aluminum is shaped and sized by being pressed through a die. For PVC and other plastic materials, injection molding is often employed, where melted plastic is injected into molds to create the headrail.

Surface Treatment for Aluminum Alloy Headrails

To enhance appearance and provide rust protection, aluminum alloy headrails of cellular shades usually undergo surface treatments. One common method is anodizing, which creates an oxide layer on the metal surface, improving corrosion resistance and visual appeal. Additionally, spraying or coating with paint provides a wide range of color and texture options to complement various interior decor styles. This spraying process can also enhance the wear resistance of the headrail. Another effective treatment is electrophoretic coating, which offers durable corrosion protection and a uniform finish for the headrail.

Fabric

The fabric is the most crucial component of a cellular shade, influencing everything from light management and heat insulation to durability and aesthetic. Let’s take a closer look at the materials and manufacturing processes involved.

Common Materials

Polyester is a widely used synthetic fiber for cellular shades, valued for its durability, wrinkle resistance, and excellent color retention. It is commonly utilized in both light filtering and blackout honeycomb blinds, offering effective light control and privacy. Another popular material is non-woven fabric, which is made by layering fibers and bonding them through heat or chemical processes. This results in a lightweight, soft, and breathable fabric that is typically used in light filtering cellular shades, providing gentle diffusion of light. While less common than synthetic fibers, some honeycomb blinds incorporate natural fibers such as cotton, linen, and cellulose. These materials offer a distinctive texture and aesthetic, and they are often featured in high-end products to meet environmental standards or specific design preferences.

Manufacturing Processes

Before cellular shades are assembled, their fabric undergoes several processes, including dyeing or printing, cutting, coating, reinforcement, antibacterial treatment, and hot press molding. Different manufacturers may use various techniques and follow distinct processing steps. Here are some common methods:

1. Cutting

The fabric is cut to specific dimensions based on design requirements. Common cutting techniques include:

- Laser Cutting: A high-energy laser beam is directed at the fabric, causing it to melt, burn, vaporize, or be blown away. This method produces smooth cuts that are suitable for a variety of materials.

- CNC Cutting: This automated process uses computer numerical control technology to program the movement and operation of the cutting tool, ensuring precision in cutting.

- Electric Cutting: This method employs rotating or reciprocating blades on an electric cutting machine to cut through the material using mechanical force.

2. Coating Treatment

Coating treatments enhance the fabric's functionality, such as light-blocking, waterproofing, and stain resistance. Techniques include:

- Hot Melt Coating: A hot melt adhesive is applied to the backside of the fabric to increase durability and functionality, including waterproofing properties.

- Spraying: Coatings are evenly applied to the fabric surface using spraying technology, improving light-blocking and UV resistance.

- Dipping: The fabric is fully immersed in specific chemical solutions to impart additional features, such as fire resistance or stain resistance.

3. Reinforcement Treatment

Reinforcement treatments involve adding supportive materials or hot melt adhesive to enhance the fabric's stability and maintain its honeycomb structure. Techniques include:

- Mesh Fiber Enhancement: Mesh fibers are embedded in the fabric to increase its strength and structural stability.

- Composite Lamination: Multiple layers of material are laminated onto the fabric to improve its overall strength and stability.

4. Hot Press Molding

Hot press molding uses specialized equipment to bond two or more layers of fabric into a honeycomb shape, applying high temperature and pressure to maintain this structure. Techniques include:

- Mold Hot Pressing: Molds of specific shapes are used to transform the fabric into a honeycomb shape through the application of heat and pressure.

- Thermal Bonding Technique: Thermoplastic materials are softened to bond multiple layers of fabric under medium to high temperature conditions.

Bottom Rail

Located at the bottom edge of the cellular shade, the bottom rail is typically a sturdy, often weighted component that helps maintain the shade’s shape and stability. The materials and processing techniques used for the bottom rail are similar to those employed for the headrail.

Material Selection

Aluminum alloy is commonly used for the bottom rails of honeycomb shades, just like for the headrails. It provides a strong yet lightweight option that resists bending or warping during regular use. Its smooth surface can undergo various finishing treatments to achieve different colors and textures, meeting diverse design and aesthetic needs. In addition to aluminum alloy, some honeycomb window shades use plastic for the bottom rails, offering a more budget-friendly alternative. Plastic is corrosion-resistant and durable in humid or corrosive environments. It can also be easily molded into different shapes and colors during production, providing significant design flexibility.

Processing Techniques

The manufacturing process for honeycomb shade bottom rails typically includes cutting, shaping, and surface finishing. The methods differ based on the material. For aluminum alloy, cutting is usually done with a saw, followed by deburring with tools or sandpaper. The aluminum is then heated and shaped through extrusion, and finalized with surface treatments like anodizing, painting, or powder coating to enhance durability and appearance. For plastic rails, lasers or high-speed rotary tools handle cutting, and melted plastic is injected into molds to set. The surface can then be finished with painting, coating, or polishing to enhance its appearance and texture.

Handle

The handle, often referred to as a "pull handle" or "lift handle," is a small but functional component designed to facilitate the operation of cordless cellular blinds. The production of these handles varies based on the material used.

Plastic Handle

Plastic handles, which are generally detachable, can be installed at any point on the bottom rail. They are typically made from durable and easily processed plastics like ABS or polypropylene. In the production process, plastic pellets are heated until they melt and then injected into molds, where they cool and form the basic shape of the handle. After they are removed from the molds, any excess material is trimmed to ensure a smooth finish. Depending on design requirements, these handles may be painted, printed, or coated to improve their appearance.

Metal Handle

In addition to plastic, metal handles are also available and are typically made from materials such as aluminum alloy, stainless steel, or zinc alloy. Once shaped and given a surface treatment, these metal handles are attached to the bottom rail either by welding them in place or securing them with screws or rivets. This combination of functionality and aesthetic appeal allows users to operate their cellular shades efficiently while also enhancing the decor.

How do Cordless Cellular Shades Work

Cordless cellular shades are honeycomb shades that operate without traditional pull cords, offering a cleaner and safer design. Under the new standard set by the Window Covering Manufacturers Association (WCMA) and the American National Standards Institute (ANSI), which took effect on June 1, 2024, most window coverings sold in the United States — whether they are stock or custom-made — must either be cordless or have inaccessible cords. These cordless shades can be operated either manually or with motorization. But how exactly do cordless cellular shades function? What mechanisms control their movement, and what devices facilitate their operation? Let’s explore how they work.

Manual Cellular Shades

Manual operation involves raising and lowering the honeycomb window shades by pulling on the bottom rail or the handle attached to it. In doing so, the cellular shades can hover at any desired height to adjust the indoor light. The physical principle behind this operation relies on the tension of springs within the headrail and lift strings to balance the weight of the shade. When the user manually lifts or lowers the shade, the tension in the spring adjusts according to the height of the shade. This balance enables the shade to remain stable at various heights without sliding down due to gravity. There are two common spring systems used in cordless cellular blinds to achieve this balance, including tension spring- and clock spring-based systems.

Tension Spring-Based System

This system mainly comprises a tension spring and two sets of pulleys, which wind the lift strings threaded through the cordless cellular shade fabric and connected to the bottom rail. The tension spring is linked to one set of pulleys. When the user raises or lowers the shade, this pulley set compresses or extends the spring, creating tension. Upon releasing the window shade, the spring tension balances the shade's weight against gravity, ensuring it remains stable at the chosen height.

Spiral Spring-Based System

This system comprises spiral springs, spools, and a shaft. When you pull down the cordless cellular window shade, the lift strings rotate the shaft, tightly winding the spring and storing elastic potential energy. As you push the cordless honeycomb shade up, the spring releases its stored energy, using rotational motion to drive the shaft and spools, which lift the cellular window shade. Once the cellular shade reaches the desired height, the system balances the spring's force against the weight of the shade, keeping it in place without slipping. Some designs may also include friction pads or other braking materials to enhance friction within the shaft and spring, further stabilizing the cordless honeycomb shade at your chosen height.

Another device in this system uses spiral springs and gears. When the user raises or lowers the cordless honeycomb blind, the force applied through the lift strings is transmitted to the gear system. As the gears turn, they twist or stretch the spiral spring, creating tension. This tension counterbalances the weight of the cordless honeycomb shade, allowing it to remain steady at the desired height. The gear system not only transfers the user's force to the spring but also reduces the effort needed to control the cordless cellular shade's movement. In some designs, a locking mechanism is included within the gear system, helping the window shade to be securely held at a specific height.

The springs are typically made from carbon steel or stainless steel, materials known for their strength, elasticity, and durability. High-quality springs can withstand over 8,000 pull cycles. Components such as gears, pulleys, and spools are often made from plastic, providing a smooth and effortless stretching experience while reducing noise from friction during use. For higher strength and durability, these components may also be constructed from metals such as steel, copper alloys, or aluminum alloys.

Motorized Cellular Shades

Motorized cellular shades are usually fitted with a small tubular motor that operates on electricity. This motor is connected to a shaft, which rotates to raise or lower the cellular shades. These window coverings can be powered by batteries or plugged directly into an electrical outlet, and some models even support solar power to boost energy efficiency. Users can control motorized honeycomb shades through a switch, remote control, or integration with smart home systems, allowing for operation via buttons, remote devices, or mobile apps.

Different types of motors, such as AC and DC motors, operate on distinct principles, resulting in variations in their internal structures. However, they generally consist of key components like stators, rotors, air gaps, bearings, and housings. Brushed DC motors also feature a commutator and brushes. The commutator is a cylindrical assembly made up of segmented copper pieces that deliver current to the rotor windings via brushes, allowing for periodic changes in current direction. In contrast, brushless motors use electronic control circuits to manage current direction and switching, often incorporating feedback from sensors like Hall effect sensors to maintain rotation. For motorized cellular shades, which require quiet, precise, and reliable movement, brushless DC motors are often preferred due to their higher efficiency, lower noise levels, and reduced maintenance needs. The specific choice of motor may vary depending on the manufacturer and the type of product.

For remote-controlled motorized cellular window shades, the headrail features an internal system that includes a control module capable of integrating a wireless signal receiver or antenna. This setup enables communication with remote controls, smartphones, and other control devices. Remote controls come in two types: single-channel and multi-channel. A single-channel remote can control only one motorized honeycomb shade, whereas a multi-channel remote can operate multiple shades simultaneously. The multi-channel functionality is pre-coded by the manufacturer before shipping.

Cell Options of Cellular Shades

Honeycomb shades are available in a variety of structure designs and cell sizes. In this section, we'll guide you through the different designs and cell size options available in the industry.

Single Cell vs. Double Cell vs. Cell-in-Cell

Single-cell honeycomb shades consist of a single layer of hexagonal or honeycomb-shaped cells that, when viewed from the side, resemble a series of small pockets. This design offers a basic level of insulation by trapping air within the individual cells, helping to reduce heat transfer and making rooms more energy-efficient.

Double-cell shades feature two layers of stacked honeycomb cells, creating additional pockets within the fabric. This dual-layer construction provides superior insulation compared to single-cell shades, as the extra layer increases the number of air pockets that trap heat, better regulating indoor temperatures and enhancing energy efficiency. Some designs even feature triple-cell honeycomb shades, which provide enhanced performance compared to single- or double-cell options.

Cell-in-cell honeycomb shades have a unique design where smaller cells are nested within larger ones, achieving a multi-layered effect. Similar to double-cell shades, cell-in-cell designs offer excellent insulation due to multiple air pockets. However, the nesting of cells can provide an even more sophisticated structure for trapping air.

Cell Sizes

Cellular shades come in various cell sizes, each offering different aesthetic and functional benefits. The choice of cell size can affect the honeycomb shade's appearance as well as its insulating properties. Here are the common cell sizes for cellular shades:

- Small Cells (approximately 3/8 inch or 10 mm): These smaller cells create a more delicate, sleek look and are suitable for smaller windows or where a more refined appearance is desired. While they provide good insulation, the smaller cells have less air space than larger cells, so the insulation is not as high as in larger configurations. Small cell honeycomb shades are ideal for shallow window depths or windows where less bulk is preferred.

- Medium Cells (approximately 1/2 inch or 12-14 mm): Medium-sized cells strike a balance between aesthetics and functionality, offering a moderate look that fits well in most room styles. They provide a good balance of insulation and appearance, being suitable for moderate climates. Medium cells are versatile and can be used in both residential and commercial settings.

- Large Cells (approximately 3/4 inch or 19 mm and above): Larger cells create a more substantial look and are suitable for larger windows or for making a bold statement. Because they contain more air, large cells provide superior insulation, making them ideal for extreme climates. They are often chosen for larger windows or sliding glass doors where enhanced insulation and a robust appearance are desired.

Opacity of Cellular Shades

The opacity of cellular shades refers to their ability to block light, with options ranging from blackout to light filtering. Blackout cellular shades are designed to completely block external light, while light filtering cellular shades allow some natural light to pass through. With these options, you can choose the level of light control that best suits your needs.

Blackout Cellular Shades

Blackout cellular shades, also known as room-darkening cellular shades, are window shades crafted to block nearly 99% of incoming light. They are made from multiple layers of fabric, featuring an opaque inner lining that typically uses aluminum foil to block light and darken the room effectively. This functionality can be achieved through several processing techniques, including lamination, coating, ultrasonic welding, heat sealing, and spray adhesive. Here’s how each method works:

- Lamination: The blackout layer is bonded to the outer layer using heat or adhesives, ensuring the fabric's integrity and maximizing its light-blocking capabilities.

- Coating: A specialized chemical coating, such as polyurethane, is applied to the base fabric to provide light blocking, UV protection, and waterproofing.

- Ultrasonic Welding: This technique uses ultrasonic waves to weld fabrics together, eliminating the need for stitching by melting and bonding the layers through high-frequency vibrations.

- Heat Sealing: Heat sealing bonds fabrics by applying heat and pressure, making it ideal for thermoplastic materials and enhancing overall durability.

- Spray Adhesive Technology: A specialized adhesive is sprayed between fabric layers to bond them while preserving flexibility.

Light Filtering Cellular Shades

Light filtering cellular shades are honeycomb shades designed to soften and diffuse natural light entering a room. Through their semi-transparent material, they achieve an effect of evenly distributing light. While they allow light in, these light filtering honeycomb shades also offer a level of privacy from outside view, which is ideal for homes situated close to neighbors or busy streets.

Day and Night Cellular Shades

Day and night cellular shades are a versatile window treatment that combines the benefits of both light filtering and blackout options in a single product. This versatility allows you to easily adjust the level of light and privacy throughout the day. The upper half features light-filtering fabric, which lets natural light in — perfect for daytime use when you want to enjoy sunlight without the harsh glare. The lower half, made of room-darkening or blackout fabric, provides enhanced privacy and significantly reduces light, making it ideal for nighttime or situations where a darker environment is needed, such as in a bedroom for quality sleep.

Features and Functions of Cellular Shades

Now that we have covered the construction, manufacturing, and operation of cellular shades, let's explore the benefits they offer. These include energy savings, noise reduction, privacy protection, and light control.

Energy Saving

One of the key benefits of cellular window shades is their energy-saving properties. Their unique honeycomb structure features interconnected pleated cells that create enclosed air pockets. Since air is a thermal insulator, these pockets effectively serve as an insulating layer that significantly reduces heat exchange. For instance, in the summer, they help keep outdoor heat from entering your home, maintaining a stable indoor temperature and reducing the need for air conditioning. In this way, cellular shades help you save electricity and lower your cooling costs.

Moreover, blackout cellular blinds generally offer better insulation compared to light filtering cellular shades. This is because blackout honeycomb shades are typically made from multiple layers, including an opaque inner layer that effectively blocks and reflects heat. This design effectively prevents external heat from entering the room and help avoid heat buildup from direct sunlight, thereby maintaining a more comfortable indoor temperature.

The energy efficiency of cellular shades is often measured by their R value, which indicates the material's ability to resist heat flow. A higher R value signifies better insulation. Typically, standard single-layer honeycomb shades have an R value between 2 and 3, while double-layer honeycomb shades and other high-performance options can achieve R values of 4 to 5 or even higher. This variation is influenced by the number of layers in the honeycomb structure, the materials used, and the overall design. Cellular window shades with higher R values can significantly reduce heat loss in winter and heat gain in summer, effectively enhancing a room’s energy conservation.

Noise Reduction

The honeycomb structure of cellular shades also plays a role in sound absorption and dampening. The air pockets not only block heat transfer but also reduce the transmission of sound through the air. Additionally, this design helps minimize sound wave resonance near windows, effectively lowering the noise that enters the room through glass and window frames. Typically made from soft materials with sound-absorbing properties, honeycomb window shades can effectively absorb certain sound vibrations, further reducing noise transfer into the room.

Privacy and Light Control

Cellular shades provide outstanding privacy protection with their seamless construction, eliminating light leakage between the fabric and headrail. This design ensures that your indoor activities remain concealed from outside view, giving you peace of mind by keeping prying eyes at bay. Whether you're in a bustling urban area or a more secluded setting, cellular shades allow you to enjoy your personal space without the worry of someone peering in.

As mentioned earlier, cellular shades come in both light filtering and blackout options, with the level of light blocking directly influencing privacy. Light filtering cellular shades subtly diffuse sunlight while maintaining basic privacy, ideal for living rooms or anywhere you want natural light without compromising seclusion. Blackout cellular shades, on the other hand, are perfect for bedrooms or media rooms, as they offer complete privacy and block out light for restful sleep or an immersive viewing experience.

One standout feature of cellular shades that offers enhanced flexibility in managing privacy and light control is the top-down bottom-up design. This unique feature allows you to adjust the honeycomb window shades by either lowering them from the top or raising them from the bottom. As a result, you can let in natural light while maintaining privacy by lowering the shade from the top or achieving a similar effect by raising it from the bottom. This adaptability makes top-down bottom-up cellular shades an excellent choice for various room settings, providing greater control over both light and privacy.

Expansion: Pleated Shades and Their Differences from Cellular Shades

Pleated shades are a type of window covering made from a single layer of fabric folded into crisp, pleated patterns, resembling a paper fan. They are usually made from lightweight materials, which may include polyester, non-woven fabrics, and even paper-like substances. The fabric can range from sheer to opaque, depending on the level of light control and privacy protection desired. As illustrated in the picture, pleated shades and cellular shades may seem similar due to their pleated design and fabric material, but they are actually distinct types of window shades. Pleated shades feature a single layer of fabric that is neatly folded into pleats. In contrast, cellular shades are constructed with two or more layers of fabric that form air pockets, resembling a honeycomb structure. Additionally, the lift strings of pleated shades are visible, whereas the lift strings in cellular shades are concealed within the air pockets.

© 2024 Hestia Blinds. All rights reserved.

Share:

Understanding Window Blinds and Shades: Functions and Features

The Complete Guide to Zebra Shades